Metal stamped parts have precision, durability, and cost-effectiveness for mass production. These stamped parts are vital to both the automotive and aerospace industries. The need for high-strength-to-weight ratio materials that aid in fuel economy as well as structural integrity has made metal stamping the go to method in producing such parts. The rapid development of the CNC machining providers has integrated automated precision tooling, which has improved the performance, consistency, and scalability of metal stamping pertaining to cost efficiency and tool life.

This article discusses the use of metal stamped parts in the automotive and aerospace sector, their advantages, applications, and the interrelation between metal stamping and CNC machining manufacturers in order to improve the production quality.

The Role and Advantage of Metal Stamping in Automotives and Aerospace Industries

Automobiles and aircrafts have intricate metal parts which have to be manufactured with high accuracy and which require modern production methods. Such global demands compel metal stamping which includes forming, cutting, bending, and assembling metal sheets through high-tonnage presses using custom designed dies. Stampings made from these processes are designed for strength while keeping the weight low to meet the demands of the automotive and aerospace industries in regard to safety and performance.

Parts like chassis, brackets, structural reinforcements, engine mounts, and fuel system components are manufactured using metal stamping for the automotive industry. Car manufacturers leverage the use of these stamped parts as they are reliable, improve gas mileage, and make cars lighter. Similarly, the aerospace industry also uses stamped parts for aircraft fuselage sections, brackets, structural supports, and engine components fabrication. Due to the harsh conditions aerospace parts experience, metal stamping enables producers to make strong, light, and anti-corrosive components which helps make airplanes safer and more fuel-efficient.

Mass production of a product with high precision is one of the benefits of metal stamping that stands out. Manual working and welding cannot be compared to stamping, in which dies that were previously meticulously crafted are used to ensure every component is precisely made. A design can be used to make thousands or even millions of identical parts with little to no difference after the die has been made. For industries such as automotive manufacturing, this level of precision is essential because of the vast number of parts that need to be integrated seamlessly into complex builds.

Another crucial benefit is efficiency and cost-effectiveness. In comparison to traditional machining, metal stamping saves production time making it more useful for high-volume productions. Stamping also reduces the necessity of employing manual operators, hence decreasing labor costs while automated stamping presses can be operated endlessly to increase productivity. In addition, due to the accurate cutting of sheet metal to maximize its utilization, metal stamping considerably decreases material waste. Due to the cost efficiency and effectiveness that high speed production provides, many manufacturers prefer turning to CNC Machining manufacturers for metal stamping solutions.

Uses of Metal Stamped Parts in Automotive and Aerospace Industry

The automotive industry makes extensive use of metal stamping for chassis reinforcements, crash protection components, transmission housings and brackets. These vehicle parts are fundamental to its structural integrity, crash resistance and passenger safety. Moreover, stamped aluminum parts that are lightweight are crucial for construction of fuel-powered and electric vehicles to save battery life and improve the driving range.

In the aviation sector, metal stamping is incorporated in the making of jet engine parts, fuselage reinforcements, supports for aircraft landing gears, and even components of the cabin interiors. Due to the critical nature of aviation safety, it is crucial to maintain optimum levels of accuracy and safety standards, leaving no room for even the smallest of errors. In aerospace applications, stamped components are subjected to rigorous quality control inspections which include non-destructive testing and measurement checks for conformity with set industry standards.

Moreover, collaborations form between stamping and CNC machining companies for the production of hybrid components that utilize both stamping and CNC precision machining. This enhances performance as well as reliability of aviation and automotive grade stamped parts as it enables the design of complex geometric, high strength integration of aerospace materials with other components.

How CNC Machining Manufacturers Assist in Metal Stamping

Although metal stamping is a relatively fast procedure, some features are detailed and precise and therefore need additional processing and machining. This is achieved with the help of CNC machining who further provide the required intricate cutting, drilling, and finishing of the stamp design which enhances the accuracy of the metal stamping.

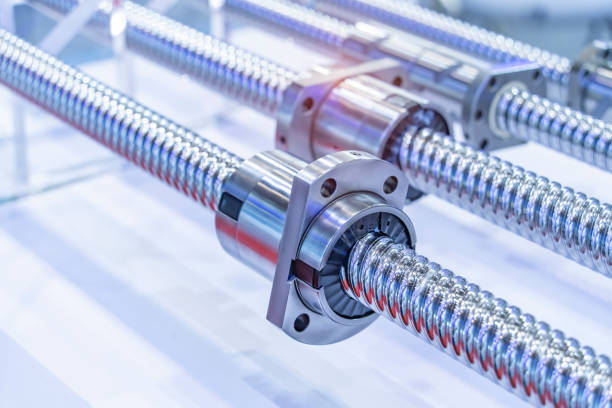

Custom stamping die and tooling are some of the most exceptional custom products that CNC machining manufacturers produce. The high precision dies for metal stamping need to be accurate to the microns and that is guaranteed with CNC machining. Multi-axis CNC milling, electrical discharge machining (EDM), and laser cutting are used by manufacturers to produce high quality and robust stamping dies that are accurate, minimize production defects, and maximize the longevity of the tooling.

In addition, metal stamping is complemented with CNC machining secondary operations like threading, tapping, and contouring. These secondary operations serve the critical function of completing parts for automotive and aerospace components to the exacting engineering and safety standards. Close tolerance stamped components paired with CNC machining are the result of integrating metal stamping with CNC machining. These parts are accurately engineered to work in highly specialized and tough environments.

Coming Developments in Metal Stamping and CNC Machining

Automation, material science, and digital manufacturing are the recent sources broadening the scope of the future in metal stamping and CNC machining. The current fourth-industrial revolution (known as Industry 4.0) that encompasses technologies like AI-based quality checks, production monitoring, and deep-learning algorithms are boosting precision and productivity. Metal stamping manufacturers and CNC machining manufacturers are increasingly adopting predictive maintenance systems, which use real-time data analytics to optimize die lifespan and prevent production downtime.

There is also a growing trend towards using lighter and stronger materials. As fuel-efficient vehicles and sustainable solutions for aerospace industries take center stage, there is a need for new metal alloys, composites, and hybrid materials that are lighter, stronger, and facilitate sustenance. These advancements in materials or advanced materials are taking CNC machining and stamping to the next level enabling the manufacturing of sophisticated aerospace and automotive parts and components.

Sustainable practices greatly influence innovations in metal stamping. Certain CNC machining companies are shifting towards less damaging processes by incorporating recycling of metallic wares, energy-effective stamping systems, and ecological coating materials which seek to mitigate harm to the environment. This can complement the movement towards making automobile and aerospace manufacturing environmentally friendly and sustainable.

Conclusion

In the aerospace automotive industries, metal stamped parts offer precision, efficiency, and durability for high-performance applications. From chassis parts in vehicles to reinforcements in aircrafts, it is clear that metal stamping provides a cost-efficient and flexible method for mass production.

The integration of CNC machining manufacturers with the metal stamping process has improved precision, quality, and overall production efficiency. Automated stamping and contemporary machining allows manufacturers to fulfill the rising needs of next generation vehicles and aircrafts without compromising industry safety and performance standards.

In the future, the advancement of technology will guarantee the continuation of the great metal stamping and CNC machining services provided in the automotive and aerospace industries. Their ability to supply light-weight, high-strength, and precision-engineered components serves as a great tool for enhancing innovation and sustainability.

Want more insights? Keep visiting Lotology for the latest updates and information!